How do you recycle? Isabella County recycling sees increase in processed material

Here's how the Mount Pleasant community and Isabella County reuse and recycle

Tucked away at a location on the north edge of Mount Pleasant, a facility recycles thousands of tons of material every year.

In Mount Pleasant or on Central Michigan University’s campus, most recycled material ends up at the Isabella County Material Recovery Facility (MRF), 4208 E. River Road. The facility recycles glass, metals, paper, cardboard and other materials.

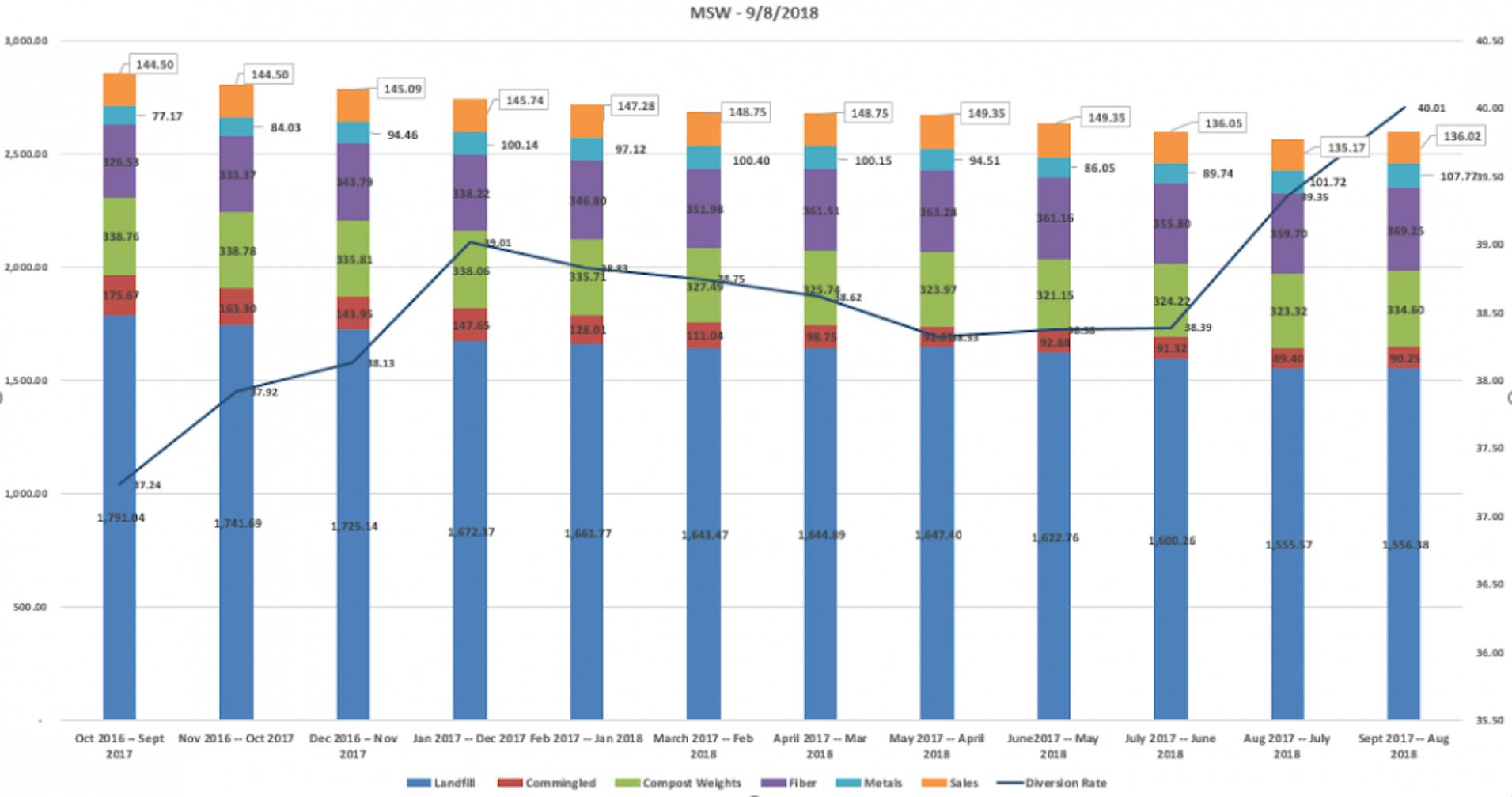

Facility director Jake Borton said the site is an unusually large operation for a county the size of Isabella County. It processed about 6,200 tons of material during its last fiscal year. It continues to see large increases in the material it receives year after year.

While the facility provides a service the community is increasingly interested in using, it struggles to cover its costs. The facility made $1.12 million in revenue during fiscal year 2018, but it had $1.16 million in expenditures. Borton said factors in the struggle to make a profit include labor cost, maintaining the baler and a decrease in commodity prices.

“We are continually trying to make up the difference (of costs),” he said.

The System

At the facility, workers use a “duel-stream" system to sort and process material. That means material is separated before it reaches the facility.

CMU Director of Facilities Operations Jay Kahn said the duel-stream process divides material into two classes: fibers (paper and cardboard) and commingle (plastic, glass and metal). This is why all CMU recycling bins have two separate containers dividing things like paper and cardboard from plastic and glass.

Workers sort materials coming off a conveyor belts into various bins on Jan. 14 at the Isabella County Materials Recovery Facility.

The facility uses this process because it's cheap, Borton said. A single-stream system – where all recyclable materials are combined into one truck or pile – is also not as clean and requires more expensive equipment to operate.

“The quality of the product coming out of a duel-stream facility is superior than what it (would) be coming out of a single-stream facility,” Borton said.

The Process

After collecting materials from the county, fibers and commingled products are dumped into separate piles. Before the materials can be sorted into more specific categories, workers must remove what’s called residual material — stuff that cannot be recycled or sold.

The most common type of residual material they find in the facility are filmy plastic products like plastic bags. It wouldn't make sense to sell them, because the facility would be required to allocate storage space, Borton said.

“It is something that can be (sold) but it’s not conducive for this sized facility,” Borton said.

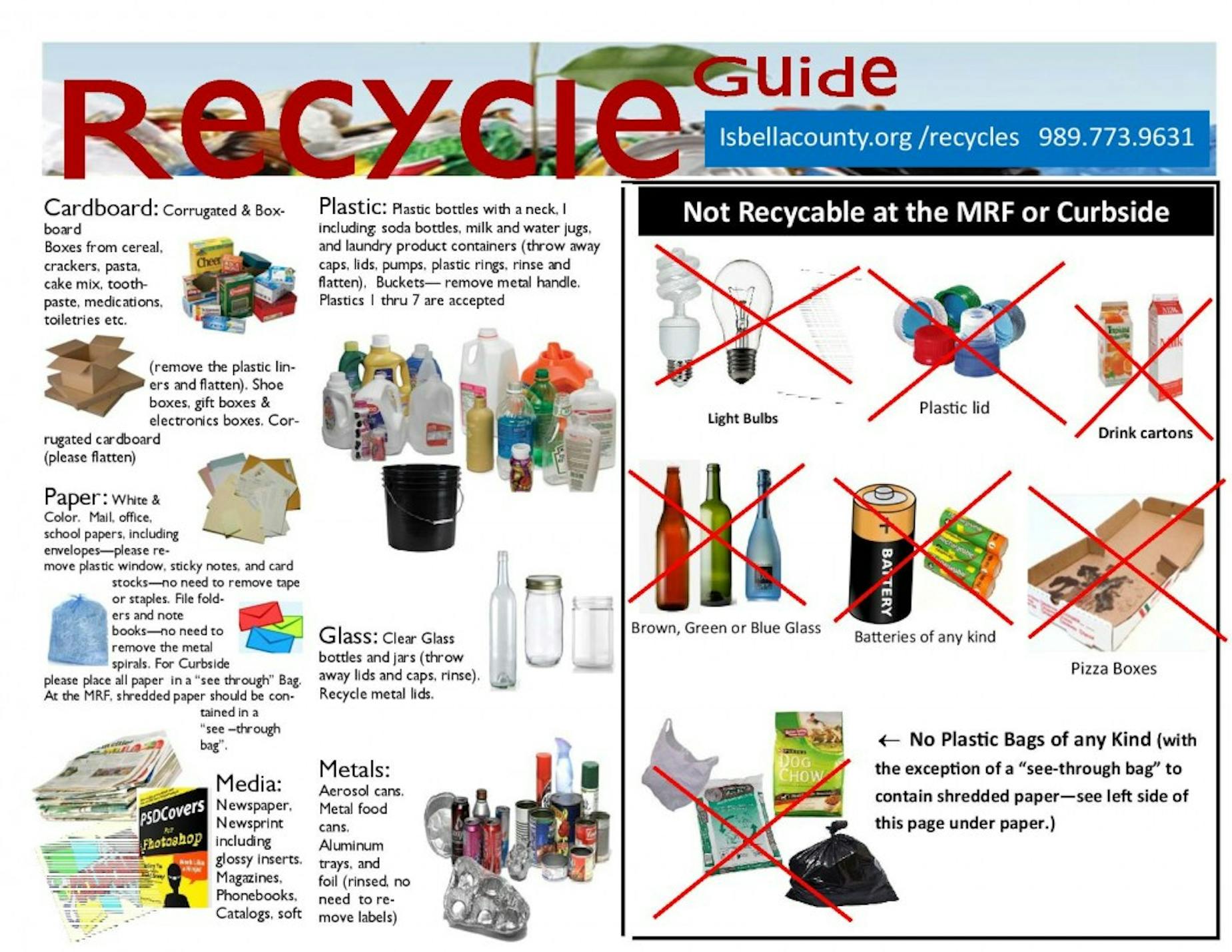

Courtesy of Isabella County.

Once the residual is removed, workers can begin organizing the materials. Fiber is carried up a conveyor belt where it’s sorted between cardboard, office paper and newspaper.

Across from the fiber operation are the commingled products. Here, different types of plastics, glass and metals are sorted through by workers and machinery.

As they are carried up the line, an electromagnet pulls up all the tin. Eventually, plastic material reaches workers, who fling empty plastic containers into designated cages.

Borton said it’s important to keep different kinds of plastic separate because certain plastics are worth more than others. If they are mixed together, they can’t make as much money.

Once the facility has enough material, it is sent through the baler. This piece of equipment condenses a large amount of material into a large rectangular mass. It is tied together with metal cables. Bales are stored in a warehouse, where they are sold and picked up. Borton said the MRF sells fiber products to brokers, who will sell directly to paper and cardboard mills.

CMU Recycling

CMU has a stripped-down operation on campus. Kahn said everything in the recycling baskets and maroon recycling tanks around campus will be sent to the county MRF. This represents two-thirds of all fibers the university recycles each year.

The remaining fiber material is sent to the on-campus powerhouse, where it’s baled and sold by the university. Kahn said printing services sends around 110 tons of fiber every year to the powerhouse and the bales make the university $8,000-10,000 per year.

The university prevents 40 percent of waste out of landfills, Kahn said. In comparison to the rest of the state, Kahn said the average diversion rate in Michigan is 15 percent.

Courtesy of Central Michigan University.

Some people on campus have other concerns with recycling at CMU. Holt junior Cloe Knop is the SGA representative of the Student Environmental Alliance and has some issues with recycling education at CMU. She thinks the university and student body could do more to be educated about what can and cannot be recycled, even if they wish something could be recycled.

She wants people to know that mixed and dirty materials are not able to be recycled, like coffee cups for instance. While they are made of material that are recyclable, she said since the cup has residual foam on it, it can not be recycled.

“People should think about what they are putting into a recycle bin,” Knop said. “There’s a lot of aspirational recyclers and I used to be one of them too. (I thought) ‘I would love if for this to be recycled, so I’m going try and recycle it.’

“Contamination is a big issue. If people recycle, I would encourage them to get informed."