When art meets awesome

3D printers allow students to create something, out of nothing

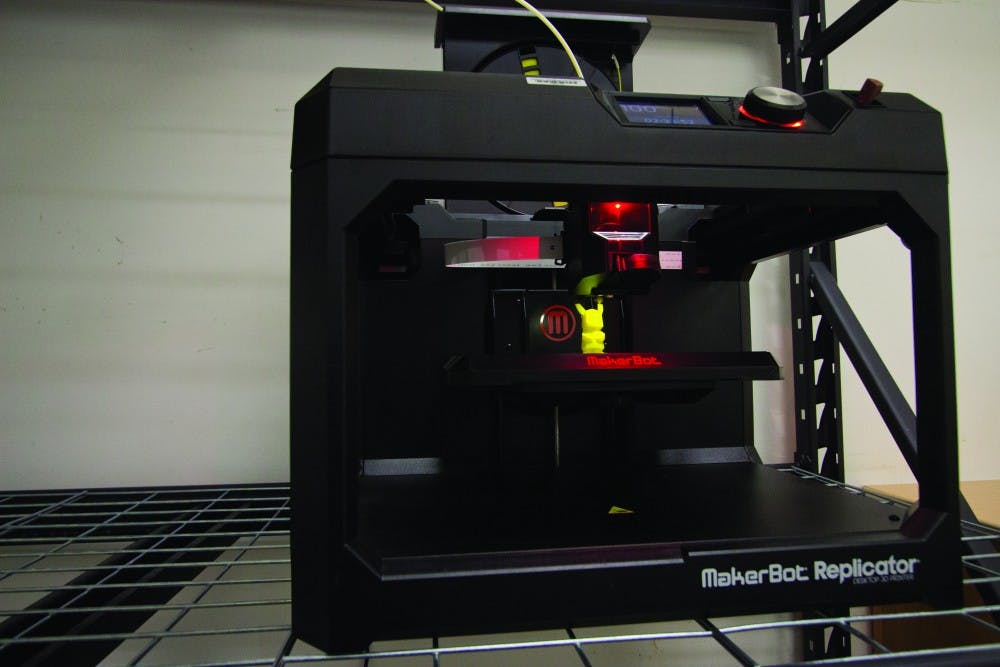

Located in Wightman Hall, Central Michigan University’s 3D printers may be able to create a multitude of items of out of thin air, but professors are still figuring out how to use them academically.

“The possibilities are essentially endless,” said ceramics instructor Greg Stahly. “In a certain sense we’re just trying to generate some interest right now. I think it’s something we haven’t really been exposed to. People don’t really understand the capabilities of a machine like this and how it can be effectively used.”

The ceramics instructor said the printers can be used for important items, not just trinkets, ranging from small household items to medical equipment.

Using computer coding, the printers are programed using a three-dimensional rendering of an object.They are then molded with a filament of ABS plastic of multiple thicknesses to sculpt the objects.

The specialized filament costs $43 per 2-pound spool. Objects are weighed after printing and are priced at 15 cents per gram.

Most objects take about two hours to print, but the computer can be programmed to continuously create objects during the day without supervision.

“It’s new technology and I think it’s intensely exciting,” Stahly said. “Do we know exactly how we’re going to implement it? No, but I’m not too concerned about us figuring it out.”

Currently, there are only three printers on campus, two in the art department and one with human environmental studies. The printer in Wightman Hall's Photo Print Lab, RM. 158, is the only one available for student use.

The cost of a 3D printer varies on the size, but they average about $1,000, Stahly said.

Larry Burditt, chair of the Art and Design department said the printers create computer-designed objects using 3D solid modeling.

The university is looking to become a center of innovation for Makerbot, the company that creates the printers, Burditt said, which would put up to 30 printers on campus.

“You have a shape in the computer that you have manipulated and then from there you export it as a file,” he said. “That goes in the software and does what you call slicing and it’s literally that. Each slice of the object is made with the thickness that you’re going to make it in. It’s off the idea of a hot glue gun.”

Objects can take hours to print on a wide range of plasticized materials, that are later hardened. Burditt said the technology and process makes sculpting much easier.

“You can sculpt without serious consequences,” Burditt said “You can create a sculpture and if you don’t like it you have an undo button. I think anyone who has done traditional hand art, theres always a certain time you wish you had an undo button.

“There’s things you can do on a computer that you can’t do by hand.”